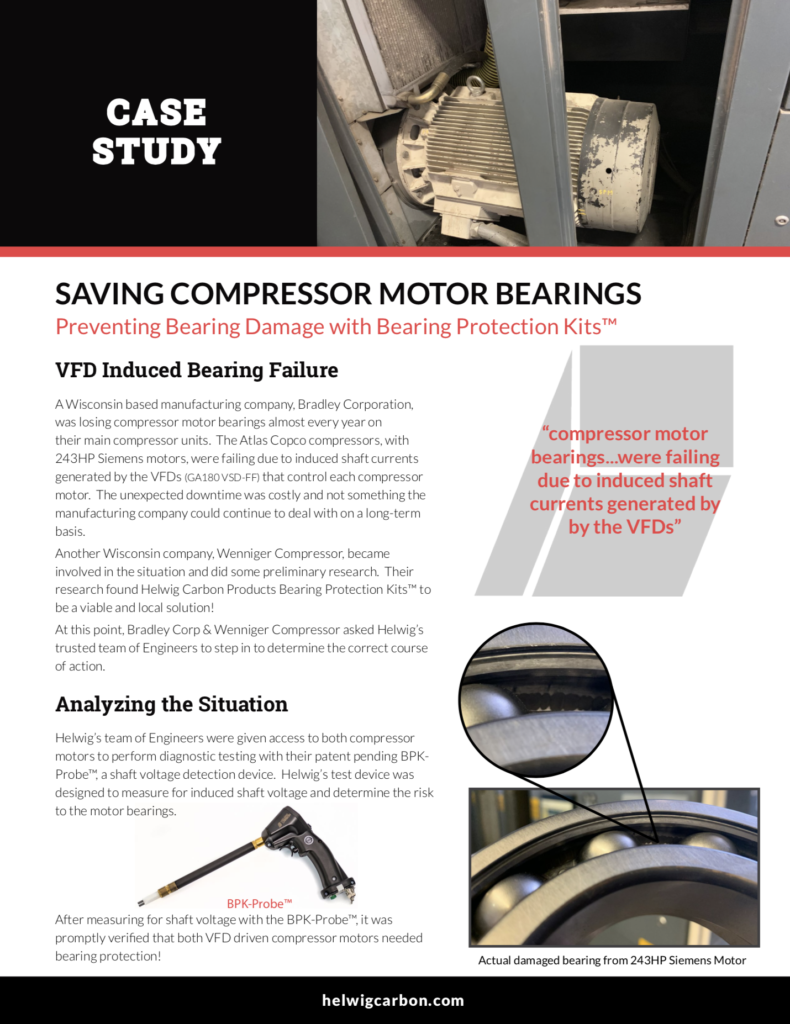

A Wisconsin based manufacturing company, Bradley Corporation, was losing compressor motor bearings almost every year on their main compressor units. The Atlas Copco compressors, with 243HP Siemens motors, were failing due to induced shaft currents generated by the VFDs (GA180 VSD-FF) that control each compressor motor. The unexpected downtime was costly and not something the manufacturing company could continue to deal with on a long-term basis.

Another Wisconsin company, Wenniger Compressor, became involved in the situation and did some preliminary research. Their research found Helwig Carbon Products Bearing Protection KitsTM to be a viable and local solution.

At this point, Bradley Corp & Wenniger Compressor asked Helwig’s team of Engineers’ help in determining the correct course of action. To read more click on case study.